4 Ways Equipment Tracking Software Can Boost Profitability

300.jpg?width=1160&name=Untitled%20design%20(3)300.jpg) Your field workers are getting the job done.

Your field workers are getting the job done.

Deliveries arrive on customers’ doorsteps on time. Your employees are moving supplies from point A to point B as expected. But instead of profits, their activities are costing you serious amounts of money. You’re in danger of going in the red, largely because of the following three things:

- Overtime pay/time card padding

- Mounting fuel expenses

- Equipment maintenance fees

The above is a scenario many small to midsize business owners in the tree trimming, landscaping, HVAC, construction, delivery, and similar industries know all too well. If it’s a scenario that keeps you up at night, too, it may be time to install fleet management solutions on your vehicles if you haven’t already.

What is Equipment Tracking Software?

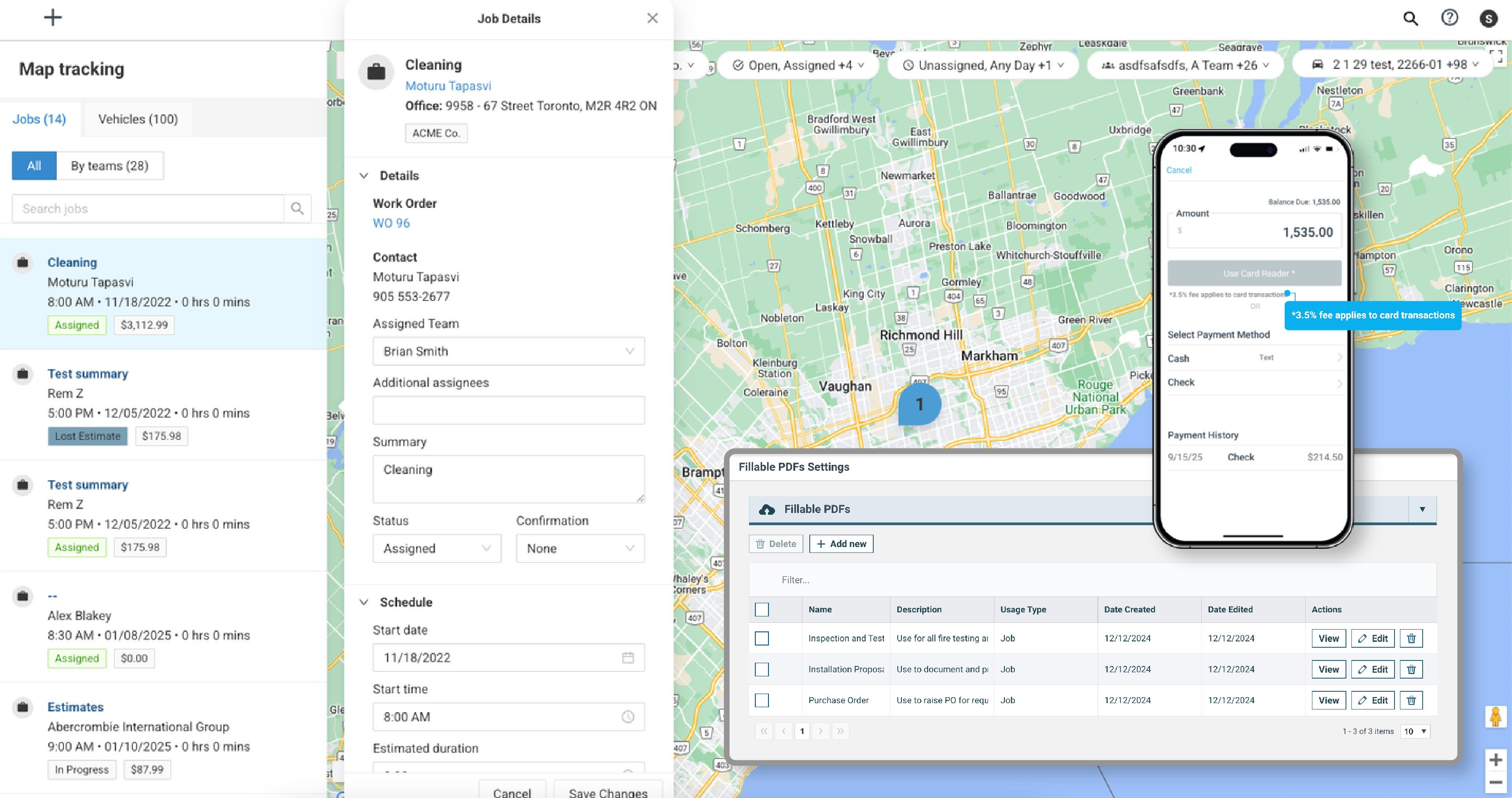

Equipment tracking or fleet management software is more than just a vehicle tracker.

Among other things, it’s equipped to monitor the following:

- Real-time location of your vehicles

- Driver routes

- Driver behavior (speeding, cornering, acceleration, and harsh braking)

- Driver’s time logs

- Whether or not a driver enters a no-go zone

- Towing activity

- Real-time alerts are delivered via email or text messages, allowing fleet managers to take the appropriate action, such as help a driver navigate their way around a traffic situation or send roadside assistance in case of a vehicle breakdown.

If properly implemented, equipment tracking software can significantly drive down your company’s operational costs and improve business profitability. Let’s examine the ways how.

How Equipment Tracking Software Boosts Profitability

1. Increased Cost Savings – Save on fuel and equipment maintenance costs

In a study cited by Trucks.com, at a price point of $2.50 a gallon, even a measly 1% in fuel savings can save fleets an annual total of $400 per truck in fuel costs. FuelEconomy.gov of the U.S. Department of Energy estimates fuel savings to be anywhere between $0.25 and $1.00 per gallon if drivers drove sensibly instead of aggressively.

Equipment tracking software monitors driver behavior that can contribute to fuel wastage, including:

- Excessive idling

- Over-revving

- Accelerating too quickly or slowly

Armed with the above data, you can issue the appropriate warning and even schedule crash courses on fuel economy for erring drivers. Emergency braking or aggressive driving can also speed up tire tread wear, and equipment tracking software helps you spot and call out such behaviors. Not only that. With a fleet management system, you also get service alerts for vehicle maintenance.

Reduce employee overtime

Employee overtime, when planned strategically, can see a company through tumultuous times. Unnecessary labor expenses, however, can run your business into the ground in no time.

A client of ours from Oregon recently installed ClearPathGPS on their vehicles. After just two months of use, they reduced overtime expenses by about 30%, which was enough to cover their initial out-of-pocket investment for the devices.

Lower insurance rates by as much as 15%

Certain insurance providers offer fleet owners discounted premiums if they have equipment tracking software installed in their vehicles. On the flipside, if you add just one driver with a bad driving record (you can obtain drivers’ records from the DMV) to your team, your fleet insurance premiums can increase by about 10%.

2. Improved Productivity

Instill employee accountability and increase productivity with equipment tracking software, which logs driver inefficiencies that will cost you money if left unchecked, such as:

- Aggressive driving

- Excessive idling

- Long lunch breaks

- Time card padding

- Side jobs

- Deliberately slowing down work

- Unauthorized travel

With a fleet monitoring system, your drivers would have second thoughts about cheating on their time cards or wasting company time. Employees who know their activities can be monitored tend to visit more customers, make more stops, and move faster between job sites.

Maximize fleet/equipment use

If you know exactly where your trucks or team of workers are, you can help them find the best routes to avoid congested roads and waiting at traffic lights with an idle engine. You can even map out routes beforehand to improve worker productivity and fuel economy.

Communicate last-minute updates to field workers

Equipment tracking tools are also equipped with communication mechanisms that allow dispatchers to send individual or group messages to their mobile employees.

3. Customer Satisfaction

Provide real-time status reports to customers. Customers asking if the HVAC technician is on his way? Or if their shipment will be delivered on time? With the data that fleet management systems provide in real time, you can provide customers with better response times and more accurate delivery estimates.

Accurate billing

Nothing is more damning to customer relations than overcharging or inaccurately billing. Equipment tracking software allows you to provide proof of service when customers question an invoice, saving you money (and a headache)!

Improving dispatch management

Does your dispatch manager spend half their day calling around to each and every driver, asking for updates on their location and estimated arrival to customers? Real-time status can dramatically improve dispatch efficiency and avoid excessive calls to drivers to see who is closest to a job site.

4. Timely Assistance to Drivers in Need

Monitor towing activities

With GPS monitoring software, a vehicle that’s moving but with the engine turned off could indicate that the equipment is being towed. You can then send help as needed.

Theft recovery

With real-time GPS trackers that update every 30 seconds and installation that prevents tampering, a heavy equipment tracking software is your best bet against theft. And because your fleet is likely one of your largest assets, you need to protect it with everything you have.

Final word

Risk management is crucial for any business – much more so for small businesses managing a fleet of vehicles and heavy equipment. If the initial cost of procuring a monitoring system is giving you pause, think about the ROI you’ll get in the long term.

Delayed deliveries and slow service technicians will not only frustrate customers, but negative word of mouth can also cost you thousands in potential business. One hijacked piece of heavy equipment can quickly set you back thousands in goods and capital equipment, and drivers running personal errands while clocked in for work is no way to be profitable. The right GPS equipment tracking software will mitigate your business risk and having full equipment tracking in place gives you peace of mind.